Stock Availability, Delays...

Yeah - it's been a problem, not just for us, and not even just in the musical instrument industry. What's going on with all the stock outages and delays?

Lately, we've had to put a few more items on backorder than we normally have to. Some of our amp and preamp manufacturers have been dealing with product shortages, and some of our basses have been suffering from availability issues as well. What's the deal?

In a lot of cases, even US-made items rely on components that are sourced worldwide. Whether it be the special neodymium magnets used in lightweight speaker drivers, the special components for digital power amps, or even something as simple as specific high-grade potentiometers, capacitors, and other electronic parts, if the production or shipment of those items is delayed, then the things that are made with those items will be delayed as well. And this has happened to some of our manufacturers lately, which has created some pretty lengthy delays, indeed.

Like I said in the headline, it's not just in the musical instrument world, either - I just had to replace a failing dishwasher in my home. I was told that the current number of backorders for the unit I wanted was 440 units (!) meaning, I'd have to wait anywhere from 8-10 months to get one. (I ended up finding a different comparable model that had only two in stock and grabbed it.)

So why are those delays happening at all?

Well, this supply-chain crisis has been building for many months as port delays are breaking records all over the place - both in outgoing (foreign) and incoming (US) ports. There are shipping delays of up to 90 days in some ports.

Another problem has been a shortage of shipping containers - those big rectangular units that they pile onto ships and unload onto tractor trailers once they get here. As a result, there are warehouses overflowing with product that they cannot ship out because there aren't any containers to put them into!

To add to that, companies in Asia and elsewhere are dealing with rising material and labor costs, staff shortages, and changing exchange rates. Some of these are COVID-related, some are not. The combination of jammed-up ports and lowered production levels has left suppliers and distributors without product to send to retailers (like us), which means a shortage of those products for you, the final customer.

To add insult to injury, the difficulty in getting things actually onto a ship has also spiked prices pretty heavily; shipping costs have skyrocketed for many countries. So this is increasing the cost of acquisition, and thereby raising the prices on down the line, for the items we actually CAN get. So if some of your favorite products have just seen a price increase, that's probably why - we've been holding our prices pretty steady for years, but there comes a point where we can't hold it off any longer.

All of that said, we're doing our best to stabilize the prices we can, and we're also working really hard to anticipate demand and get as much stuff on hand as we can. But there are some issues far up the supply chain that we cannot really do anything about.

Just thought I'd give you a heads-up on what is happening. Our customers are used to us having a well-stocked warehouse and super-quick shipping; so if that doesn't happen, at least you know we're trying our best!

Recent Posts

-

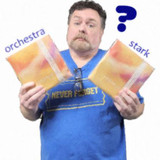

Pirastro's Perpetual Bass Strings - Do I want Stark, Medium, or some combination?

I just spent the time writing this up to post in a thread at Talkbass, so I figured I'd also share i …Nov 12th 2025 -

Preserving our Humanity

Our site has a very distinctive style and flow. And that comes from our longtime dedication to being …Sep 3rd 2025 -

What can Brown do for you? Nothing good, at least lately.

I really don't think I've ever publicly called out any other companies, so this is a first. But I've …Aug 13th 2025